Table of Contents

Slip On Flanges, Inconel 625 Slip On Flanges, ASTM A182 SS 304 Slip On Flanges, 304 Stainless Steel Slip On Flanges, UNS N08904 Slip On Flanges, UNS S30400 Slip On Flanges, UNS S31000 Slip On Flanges, DIN 1.4301 Slip On Flanges, Duplex 31803 Slip On Flanges, ASME SA182 Duplex 2205 Slip On Flanges

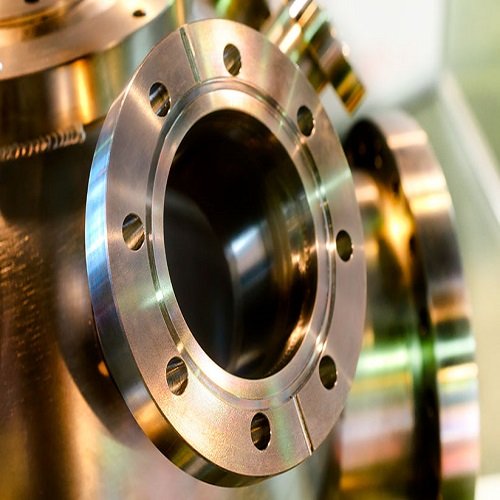

Multiple industries regularly employ ASTM A182 SS 304 Slip On Flanges to securely link pipes and other machinery. These flanges are created to be slid onto the pipe and welded into position, producing a dependable and effective connection. Slip-on flanges have particular features making them suitable for certain applications, and it is critical to comprehend these features for proper utilization in industrial settings.

Installation speed is one of the main advantages of ASME SA182 SS 316 Slip On Flanges. These flanges can be easily fitted onto pipes, making the alignment and connection of pipes a swift and straightforward process. After fitting, slip-on flanges can be welded to the pipe, guaranteeing a strong and watertight joint. The simplicity of installation makes these flanges a preferred option for industries like oil and gas, petrochemical, and water treatment plants that need to frequently assemble and disassemble pipes.

UNS N08904 Slip On Flanges boast great versatility due to their wide array of sizes, materials, and pressure ratings. Depending on the application, they can be manufactured from carbon steel, stainless steel, or alloy steel. Additionally, slip-on flanges come in different facing types, including the raised face (RF), flat face (FF), and ring-type joint (RTJ), enabling compatibility with multiple piping systems.

DIN 1.4301 Slip On Flanges are known for their cost-efficiency. They are usually more affordable than weld neck or threaded flanges because they require less material and machining. Furthermore, they are easier and quicker to set up, which can help in saving labour costs and minimise downtime during installation or maintenance.

Duplex 31803 Slip On Flanges offer great resistance to corrosion and strength. Depending on the material, these flanges can tolerate severe conditions, corrosive materials, and heavy-duty applications. They are created to establish a strong and dependable connection that can manage the intensity of industrial work processes, ensuring long-term effectiveness and dependability.

Our company is extremely meticulous when packaging 304 Stainless Steel Slip On Flanges to ensure their safe shipping and arrival. We use premium packaging elements such as sturdy cardboard boxes, foam padding, and securing coverings to avoid any damage during transit. Furthermore, we precisely label the packages with product details and handling directions to guarantee adequate management. Our packaging approach is developed to comply with industry standards and ensure our slip-on flanges reach our clients in perfect condition, prepared for immediate use in their industrial purposes.

Duplex 31803 Slip On Flanges Stockist, UNS N08020 Slip On Flanges Manufacturer, UNS S31000 Slip On Flanges Stockist, DIN 1.4301 Slip On Flanges Stockist, ASME SA182 Duplex 2205 Slip On Flanges Stockist, Hastelloy C276 Slip On Flanges Stockist, ASME SA182 SS 316 Slip On Flanges Supplier

| Specifications | : | ASME B16.5 SLIP ON FLANGE |

| Size | : | 1/2"NB TO 24"NB IN |

| Flange Face Type | : | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Class / Pressure | : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

Stainless Steel

- Stainless Steel 304 Slip On Flanges

- SS 304L Raised Face Slip On Flanges

- UNS S30400 Slip On Flanges

High Nickel

- Inconel 600, 601 Raised Face Slip On Flanges

- Nickel Alloy 200 Slip On Flanges

- Titanium Grade 2 Slip On Flanges

Carbon Steel

- UNS K03504 Slip On Flanges

- LF3 Slip On Flanges

- ASME B16.47 Carbon Steel Slip On Flanges

| CL | 150 | 300 | 600 | 900 | 1500 | 2500 |

| DIA A |

30 | 38 | 38 | 38 | 38 | ... |

| DIA D |

90 | 95 | 95 | 120 | 120 | ... |

| THK B |

9.6 | 12.7 | 14.3 | 22.3 | 22.3 | ... |

| 11.2 | 14.3 | 20.7 | 28.7 | 28.7 | ... | |

| DIA G |

35.1 | 35.1 | 35.1 | 35.1 | 35.1 | ... |

| DIA K |

60.3 | 66.7 | 66.7 | 82.6 | 82.6 | ... |

| H | 14 | 21 | 22 | 32 | 32 | ... |

| 15.6 | 22.6 | 28.4 | 38.4 | 38.4 | ... | |

| NO. L |

4 | 4 | 4 | 4 | 4 | ... |

| DIA L |

15.9 | 15.9 | 15.9 | 22.2 | 22.2 | ... |

| Stud Bolts Diameter x Length | ||||||

| DIA (in) |

1/2 | 1/2 | 1/2 | 3/4 | 3/4 | ... |

| Len mm |

55 | 65 | 75 | 110 | 110 | ... |

| SS Flanges | USD $2.19 - $10.16 / Piece (FOB Price) on request |

| Duplex & Super Duplex Flange | USD $10.59 - $35.68 / Piece (FOB Price) on request |

| High Nickel Alloys Flanges | USD $8.50 - $20.49 / Piece (FOB Price) on request |

| Cupro Nickel Flanges | USD $5.56 - $10.98 / Piece (FOB Price) on request |

| Carbon Steel Flanges | USD $2.59 - $7.56 / Piece (FOB Price) on request |

| Preview | Products | UNS | DIN |

|---|---|---|---|

|

Stainless Steel Slip On Flanges | UNS S30400, S30403, S31600, S31603 Slip On Flanges | 1.4301, 1.4306, 1.4401, 1.4404 Slip On Flanges |

|

Duplex / Super Duplex Steel Slip On Flanges | UNS S31803, S32205, SAF-2205, S32750, S32760, SAF-2507 Slip On Flanges | 1.4462, 1.4410 Slip On Flanges |

|

Copper Nickel Slip On Flanges | UNS C70600, C71500 Slip On Flanges | 2.0872, 2.0882 Slip On Flanges |

|

Alloy Steel Slip On Flanges | UNS K41545, K90941, K11597, K21590 Slip On Flanges | 1.7362, 1.7386, 1.7335, 1.7380 Slip On Flanges |

| American Steel Slip On Flanges Standard | |

| Standard Code | Standard Name |

| ANSI ASME SA-182 | Slip On Flanges |

| ANSI ASME B16.5 | Slip on Flanges, sortj, soff, rfso flange |

| ASME – B 16.36 | Slip on Flanges |

We make sure that our every product is made of high quality raw material. We thoroughly test each and every product before dispatching it to our customers. one of the most trusted manufacturers and suppliers of fasteners and bolts which are applicable in various industries.

- Power Generation Industries

- Food Processing Industries

- Oil & Gas Industries

- Sugar Industries

- Petrochemical Industries

We known for its accurate and perfect dimensions. We thoroughly test all our products before shipping them to the customers. We carry out destructive as well as non-destructive tests on all our products.

- Eddy Current Examining

- Power Generation Industries

- Hydrostatic Analysis

- Positive Material Recognition

- Pitting Protection Test

We uses the most safest and the most effective ways of packaging for all types of deliveries. We pack our goods in various ways such as:

- Wooden Boxes

- Wooden Pallets

- Shrink-Wrapped

- Carton Boxes

- Wooden Boxes

Jamshedpur, Rajkot, Lahore, Geoje-si, Jakarta, Kolkata, Gimhae-si, Vung Tau, Karachi, Istanbul, Manama, Kuwait City, Howrah, Hanoi, Hong Kong, New Delhi, Calgary, Ranchi, Muscat, Hyderabad, Mumbai, Moscow, Kuala Lumpur, Nashik, Busan, Ho Chi Minh City, Singapore, Aberdeen, Algiers, Cairo, Chandigarh, Dallas, Milan, Ahmedabad, Houston, Ulsan, Visakhapatnam, Colombo, New York, Chennai, Toronto, Brisbane, Petaling Jaya, Jaipur, Navi Mumbai, Atyrau, Jeddah, Secunderabad, Kanpur, Gurgaon, Bangkok, Indore, Rio de Janeiro, Montreal, Al Khobar

Poland, Thailand, Gabon, India, Tibet, Australia, Nigeria, Angola, Sri Lanka, Libya, Hong Kong, Mexico, Kuwait, Switzerland, Bhutan, Bulgaria, Nepal, Singapore, China, Kenya, Croatia, Japan, Sweden, Trinidad & Tobago,Tunisia, Egypt, France, Bolivia, Peru, Mexico, United Kingdom, Austria, Portugal, United Arab Emirates, Jordan, Ecuador, Nigeria, Chile, Czech Republic, Philippines, Iran, Chile, Netherlands, Canada, Namibia, Norway, Puerto Rico, Yemen, Romania, Mongolia, Brazil, Costa Rica, South Korea, Finland, Lithuania, Italy, Qatar, Colombia, Russia, Lebanon